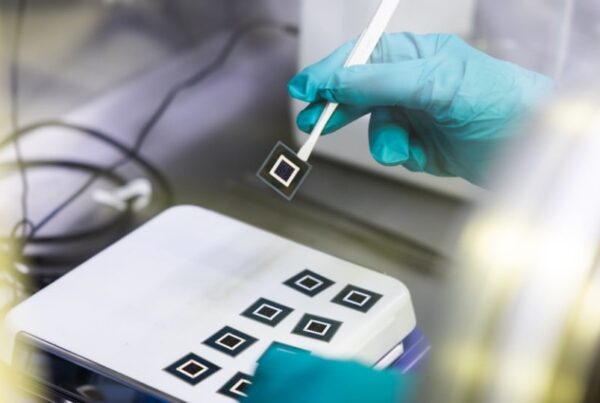

The facility will produce crystalline silicon solar PV modules, incorporating advanced technologies like TOPCon, half-cut, and bifacial cells with fully automated systems to enhance efficiency. It will rely on imported equipment such as tabber-stringers, laminators, and sun simulators to ensure high-quality and efficient module output.

The company, specialising in rooftop solar projects, said it is building a module assembly plant to reduce cost fluctuations, speed up project timelines, strengthen supply chain reliability, and boost profit margins.

According to Solarium, this move is part of its backwards integration plan to gain better control over critical components in engineering, procurement, and construction (EPC) projects, where solar modules typically account for 50% to 60% of the total project cost. The company also plans to build mounting structures – which represent about 10% of the project cost, according to Solarium – at its facility in the state of Gujarat.

Ankit Garg, managing director of Solarium, said that the company aims to fully backwards integrate its operations to strengthen its supply chain and boost profitability. He explained that at 85% capacity utilisation, the new plant could generate over INR10 billion in revenue through module sales. For in-house use of these modules, the company expects to improve project gross margins by 5%-8% by cutting third-party markups.

According to the Ministry of New and Renewable Energy (MNRE), the state-wise installed capacity of renewable power as of May 2025 shows that Gujarat has an installed capacity of 20GW.