As a result, the company claimed that its US offtake customer, Hanwha Qcells, “Is not able to wait any longer for delivery of product that consistently meets the requirements at the correct levels and can be delivered at the needed volumes.”

REC said the Moses Lake facility will be closed completely within three months, and its workforce will be “reduced accordingly.” It will retain the equipment needed to produce silicon gases, which it said would allow it to capitalise on potential future demand for silicon anode or other gases.

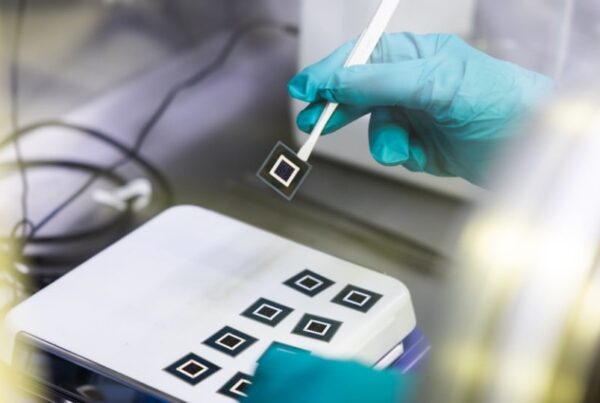

REC signed a supply agreement with Qcells – a subsidiary of Korean conglomerate Hanwha Solutions – in September 2023. The deal was the first step in Qcells’ plan to produce entirely US-made solar modules, centred on its ingot-module manufacturing hub in the state of Georgia. However, the closure of Moses Lake throws this plan into doubt.

Hanwha Solutions also became the majority shareholder of REC Silicon in April 2022, changing the company’s executive roster and announcing plans to restart production at the then-dormant Moses Lake facility. Production at Moses Lake was delayed from Q4 2023 until Q2 2024, during which time REC announced the shutdown of another polysilicon production facility in Montana.

This news has raised some eyebrows across the solar industry. Polysilicon market expert Johannes Bernreuter said in a post on LinkedIn: “The company’s argument…that its only polysilicon customer Qcells USA Corp., a subsidiary of the South Korean Hanwha Group, ‘is not able to wait any longer for delivery of product’ is strange as the start-up of ingot and wafer production at Qcells has been delayed to mid-2025.”

Bernreuter also pointed to “inconsistencies among REC Silicon’s recent statements on polysilicon purity and the qualification test.”

In May 2024, the company said: “Most of the key quality measures for the product have been met.”

More broadly, efforts to bring polysilicon and ingot/wafer production capacity onshore to the US have moved slowly. One of very few potential producers, Highland Materials, announced plans for a new facility in April 2024. PV Tech Premium took a deep dive into the challenges that US companies face in trying to bring the most upstream portions of the solar supply chain – polysilicon, ingots and wafers – to the US last year.

On top of technical barriers, the cut-throat price competition among the major Chinese producers, which has seen prices plummet over the last 1-2 years, has proved a major stumbling block.

Earlier this week, PV Tech reported that Tongwei Solar and Daqo New Energy – two of the largest Chinese polysilicon manufacturers – would cut their polysilicon production in an effort to address the rampant price competition and overcapacity in the industry.

More to follow…