The facility will leverage “AI-enabled architecture,” confirmed CEO of Premier Energies, Chiranjeev Saluja.

Moreover, in a bid to “diversify the key equipment supply chain”, chief strategy officer of Premier Energies, Sudhir Reddy said that 60% of the equipment for this line has been sourced from Europe.

The New Delhi-headquartered company aims to scale up its annual nameplate capacity to 8.4GW in solar cells and 11.1GW in modules, more than doubling its current capacities by June of next year. In a conversation with PV Tech last month, Premier Energies’ chief business officer Vinay Rustagi outlined the company’s strategy (Premium access), noting that they clearly understand the government’s direction for solar cells, modules, wafers and ingots to be made in India, for India and beyond and are aligning their plans accordingly.

Recently, Premier Energies teamed up with Mono and multicrystalline wafer producer Sino-American Silicon Products Inc (SAS) to establish a 2GW per annum silicon wafer manufacturing facility in Naidupeta, Andhra Pradesh, India.

The companies formed a 74:26 joint venture, with Premier holding the majority stake, to slice polysilicon ingots into wafers for use in solar PV cells and modules, combining Premier Energies’ production capacity with SAS’s semiconductor wafer capabilities. The plant is expected to begin commercial operations in June 2026.

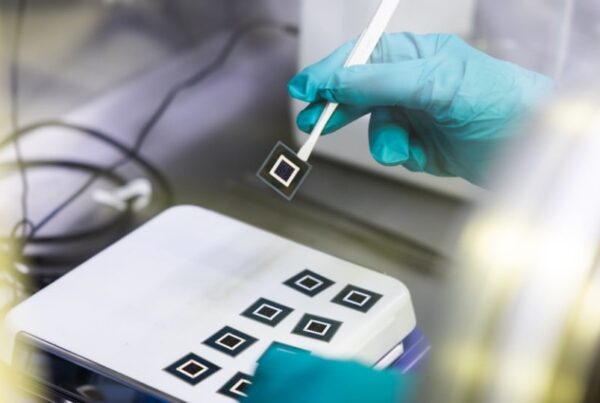

Additionally, the company has launched a 1GW solar factory in the Maheshwaram industrial zone in Hyderabad, Telangana. Currently, Premier Energies has an annual nameplate capacity of 3.2GW and 5.4GW for solar cells and modules, respectively.