The furnaces from the shipment employ the Czochralski (CZ) crystal growth method and are equipped with fully automated control systems. This allows for precise management of critical parameters, such as temperature gradients, pulling speed and rotation speed during the crystal growth process.

In total, the company will deploy 120 monocrystalline silicon growth furnaces and other advanced equipment to the Indonesian plant in stages.

Construction on the wafer-slicing plant began in April 2024 and the company expects to begin trial production in May this year.

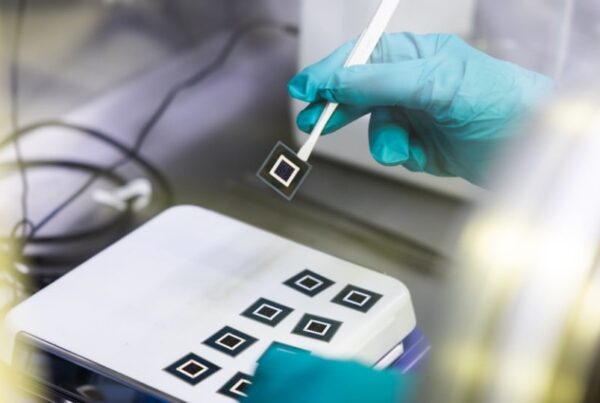

Once operational, the plant will produce monocrystalline silicon rods and large-size silicon wafers, including 182mm and 210mm.

The Indonesian wafer manufacturing plant is one of many solar manufacturing hubs the company has in Southeast Asia. Gstar has an operational solar cell plant in Thailand – with a 3GW annual nameplate – and module assembly plant in the Philippines that is in the equipment installation and commissioning phase. On top of these two manufacturing plants, the company also has an aluminium frame manufacturing plant in Laos that is operational.

Outside of Southeast Asia, the company aims to build a module assembly plant in the United Arab Emirates (UAE). Through a memorandum of understanding with Middle Eastern investment company Siraj Group, the company is targeting 2GW of annual nameplate for solar modules in the country.