Enertis Applus+, the global quality control and testing firm, is providing supply chain quality control and assurance services to a 2.5GW portfolio of solar PV projects across the US.

The company’s services focus on mitigating long-term risk in PV projects by preventing the purchase of non-reliable or unethically traced components. In particular, it said that it has focused on ensuring that risks or exposure to unethical labour practices from polysilicon production in Xinjiang, China, were ruled out. In June, the US introduced the Uyghur Forced Labor Prevention Act to rule out imports of products from the province.

Enertis also said that it acted, and will act, as a technical advisor during negotiations with the projects’ main component suppliers, ensuring that manufacturing quality and technical standards were upheld.

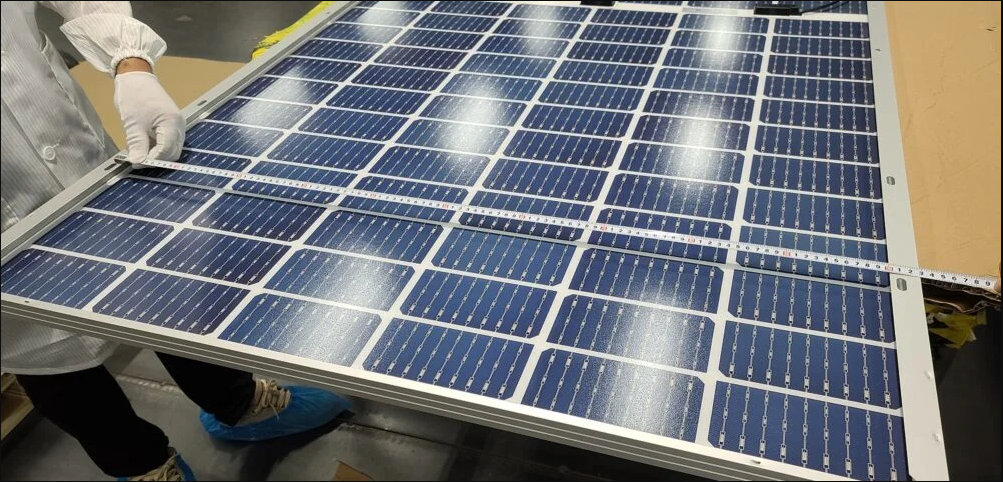

The modules used in the projects came from seven suppliers with factories in Vietnam, India, Cambodia and Thailand. A recent US Department of Commerce investigation found that some solar manufacturers in Southeast Asia have been circumventing import duties on Chinese PV cells. Enertis said that it audited these factories and supervised manufacturing processes to detect non-conformities and evaluate procedures.

All of the modules inspected used bifacial mono-PERC cells, according to Enertis. The projects will be located in Texas, Ohio, Illinois, Louisiana, West Virginia, New York, and Maine and range in size from 50MWp to over 600MWp.

Traceability is an increasingly pressing issue for the solar industry, both in the US and elsewhere. PV Tech discussed the rising scrutiny on European supply chains, and the potential solution in domestic manufacturing, last month.