Researchers at the Massachusetts Institute of Technology (MIT) have unveiled a new ‘paper-thin’ solar PV cell that can be applied to a variety of surfaces to generate highly integrable, versatile solar energy, they say.

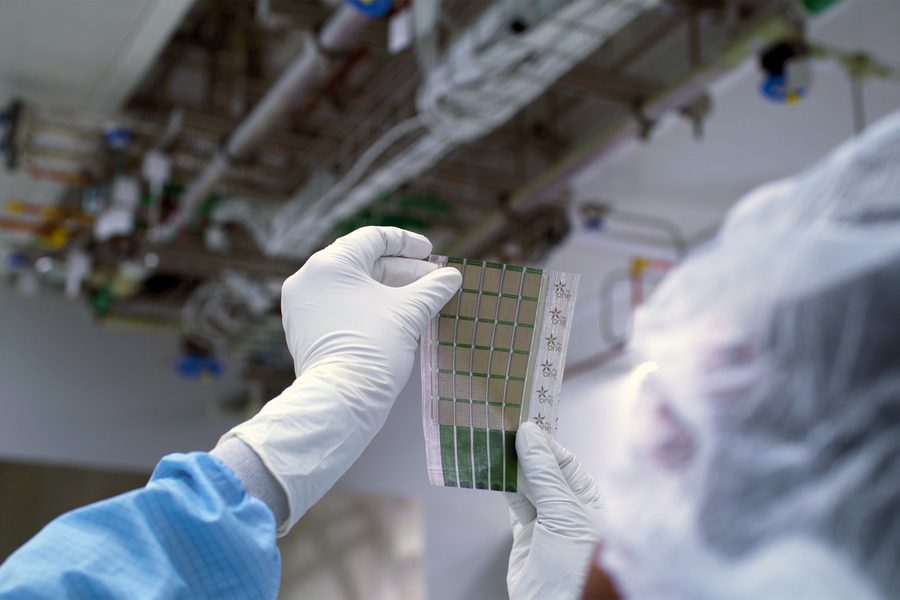

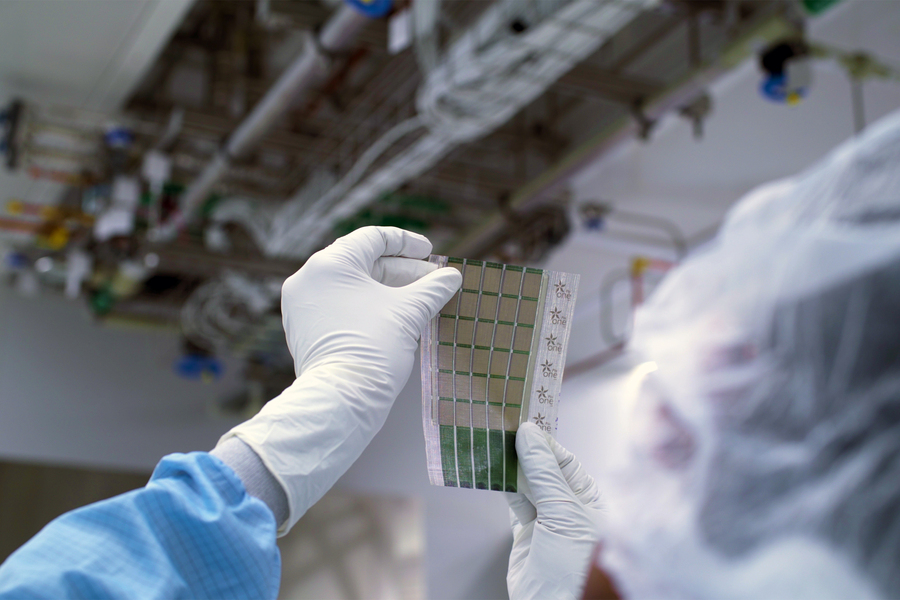

Using nanomaterials in the form of printable electronic inks, the solar cell structure is coated using a slot-die coater, which deposits layers of the electronic materials onto a prepared, releasable substrate that is only 3 microns thick, and using screen printing (a technique similar to how designs are added to silkscreened T-shirts), an electrode is deposited on the structure to complete the solar module.

The researchers can then peel the printed module, which is about 15 microns in thickness, off the plastic substrate, forming an ultralight solar device.

The device can then be adhered to a lightweight material known commercially as Dyneema, weighing only 13g per square metre.

The cells are yet to be scaled up to industrial manufacturing levels, and would need to be encased in another protective material to prevent them from degrading once exposed to the environment. MIT said that the carbon-based organic material used in their fabrication could change through interaction with moisture and oxygen, thus damaging its performance.

The research claimed that the modules could generate 730W/kg under test conditions when freestanding, and around 370W/kg when deployed on the Dyneema fabric.

“Encasing these solar cells in heavy glass, as is standard with the traditional silicon solar cells, would minimise the value of the present advancement, so the team is currently developing ultrathin packaging solutions that would only fractionally increase the weight of the present ultralight devices,” said Mayuran Saravanapavanantham, one of the researchers.

The research said that the cells could be applied to tents and shelters deployed in emergency response zones, turned into wearable power fabrics, integrated into the sails of ships to provide power at sea or adhered to the wings of a drone to extend its flight duration.

Solutions to the apparently high levels of degradation, and the potential scalability of the cells, weren’t mentioned. The research is funded, in part, by Italian energy company Eni through the MIT Energy Initiative, the US National Science Foundation, and the Natural Sciences and Engineering Research Council of Canada.